A Suspension Stiffness Optimization for Driving System in High-speed Train with the Built-in Axle Box Based on Orthogonal Test

-

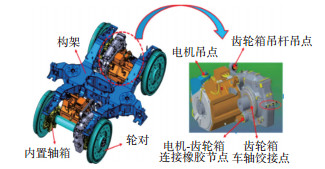

摘要: 驱动系统作为高速列车动力转向架的核心子系统,是高速列车安全运行的重要保障,但随着运行速度的不断提高,高速列车的可靠安全运行受到严重挑战。为了减小轴箱内置式高速动车驱动系统悬挂节点的动态载荷,降低驱动系统关键部件的振动水平,对驱动系统悬挂刚度进行了优化研究。基于多体系统动力学理论,综合考虑轨道随机不平顺激扰、牵引动力传递和齿轮啮合作用等因素的影响,建立了轴箱内置式高速动车动力学模型;利用正交试验设计方法,以减小牵引电机吊点悬挂载荷和齿轮箱车轴铰接点垂向载荷为优化目标,研究牵引电机吊点、齿轮箱吊杆吊点、电机-齿轮箱连接点的悬挂刚度对车辆关键部件振动加速度和驱动系统悬挂节点动态载荷的影响规律;并采用极差分析法对其影响规律进行分析,获得驱动系统悬挂刚度的最优匹配组合。研究结果表明:与原始设计的驱动系统悬挂刚度相比,参数优化后牵引电机吊点的纵向载荷最大值减小22.3%, 横向载荷最大值减小37.9%,垂向载荷最大值减小9.8%,齿轮箱车轴铰接点的垂向载荷最大值减小9.1%;此外,驱动系统悬挂刚度优化后的牵引电机、齿轮箱、轴箱的横向振动加速度均明显减小。Abstract: As the core subsystem of the power bogie of high-speed trains, the drive system is an important guarantee for the safe operation of high-speed trains. However, with the continuous increase in operating speed, the reliable and safe operation of high-speed trains is seriously challenged. To reduce the dynamic loads on the suspension nodes of the axle box built-in high-speed dynamic vehicle driving system and to reduce the vibration level of the key components of the driving system, this paper carries out an optimization study on the suspension stiffness of the driving system. To reduce the dynamic loads and the vibration levels of components in the driving system, an optimization analysis of the suspension stiffness is performed in this study. Based on the multi-body system dynamics theory, the axle box built-in high-speed locomotive dynamics model is established by comprehensively considering the effects of track random uneven excitation, traction power transmission and gear meshing. Using the orthogonal test design method, with the optimization objective of reducing the suspension load at the traction motor lifting point and the vertical load at the axle articulation point of the gearbox, the influence of the suspension stiffness of the traction motor lifting point, the gearbox boom lifting point, and the motor-gearbox connection point on the vibration acceleration of the key components of the vehicle and the dynamic load at the suspension nodes of the driving system are investigated. The influence law is also analyzed by using the extreme difference analysis method to obtain the optimal matching combination of the suspension stiffness of the driving system. The results show that the maximum longitudinal, lateral, and vertical suspension loads of the motor with optimized parameters are reduced by 22.3%, 37.9%, and 9.8%, respectively. Meanwhile, the vertical load between the gearbox and wheel axle is reduced by 9.1%. The lateral vibration accelerations of the motor, gearbox, and axle box are significantly reduced.

-

表 1 驱动系统悬挂刚度径轴比及范围

Table 1. Ratio of radial to axis and range of the driving system suspension stiffness

因素 刚度径轴比 刚度范围/(MN/m) 电机-齿轮箱橡胶节点刚度A 3.7 20~35(径向) 电机吊点刚度B 0.357 45~70(轴向) 齿轮箱吊杆节点刚度C 17 29~66(径向) 表 2 因素水平表

Table 2. Orthogonal factors table

因素 水平序号 水平对应的刚度值/(MN/m) 电机-齿轮箱橡胶节点刚度A 1、2、3、4、5 17、22、27、32、37 电机吊点刚度B 1、2、3、4、5 40、48、56、64、72 齿轮箱吊杆节点刚度C 1、2、3、4、5 20、32、44、56、68 表 3 驱动系统悬挂刚度正交表

Table 3. Orthogonal table of suspension stiffness of the driving system

单位: MN/m 刚度组合序号 电机-齿轮箱橡胶节点刚度A 电机吊点刚度B 齿轮箱吊杆吊点刚度C 1 17 40 20 2 17 48 32 3 17 56 44 4 17 64 56 5 17 72 68 6 22 40 32 7 22 48 44 8 22 56 56 9 22 64 68 10 22 72 20 11 27 40 44 12 27 48 56 13 27 56 68 14 27 64 20 15 27 72 32 16 32 40 56 17 32 48 68 18 32 56 20 19 32 64 32 20 32 72 44 21 37 40 68 22 37 48 20 23 37 56 32 24 37 64 44 25 37 72 56 表 4 优化前后的驱动系统悬挂刚度

Table 4. Suspension stiffness of the driving system before and after optimization

单位: MN/m 参数名称 原始参数 优化参数 电机-齿轮箱连接橡胶点径向刚度 22 27 电机吊点轴向刚度 56 40 齿轮箱吊杆节点径向刚度 56 68 -

[1] 刘禹清, 陈再刚, 閤鑫, 等. 复杂机车振动环境下牵引电机轴承服役寿命评估[J]. 力学学报, 2022, 54(7): 1820-1829. https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202207006.htmLIU Y Q, CHEN Z G, GE X, et al. Service life evaluation of traction motor bearings in complicated vibration environment of a locomotive[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(7): 1820-1829. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-LXXB202207006.htm [2] LATA M. The modern wheelset drive system and possibilities of modelling the torsion dynamics[J]. Transport, 2008, 23(2): 172-181. doi: 10.3846/1648-4142.2008.23.172-181 [3] ALFI S, MAZZOLA L, BRUNI S. Effect of motor connection on the critical speed of high-speed railway vehicles[J]. Vehicle System Dynamics, 2008, 46(S1): 201-214. [4] HUANG C H, ZENG J, LIANG S L. Influence of system parameters on the stability limit of the undisturbed motion of a motor bogie[J]. Journal of Rail and Rapid Transit, 2014, 228(5): 522-534. doi: 10.1177/0954409713488099 [5] 徐坤, 曾京, 黄彩虹, 等. 高速动车电机架悬参数对转向架动力学性能影响研究[J]. 振动与冲击, 2018, 37(20): 95-100, 108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201820015.htmXU K, ZENG J, HUANG C H, et al. The influence of motor elastic bogie-suspended parameters of high-speed vehicles on the dynamic performance of bogies[J]. Journal of Vibration and Shock, 2018, 37(20): 95-100, 108. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZDCJ201820015.htm [6] 罗赟, 陈康, 金鼎昌. 270 km·h-1动力车驱动制动单元悬挂参数的优化[J]. 中国铁道科学, 2004, 25(2): 62-66. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTK200402013.htmLUO Y, CHEN K, JIN D C. Optimization of suspension parameters of brake-unit driven by 270 km·h-1 power unit[J]. China Railway Science, 2004, 25(2): 62-66. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTK200402013.htm [7] 罗赟, 孙永鹏, 张红军, 等. 架悬C0-C0轴式机车电机布置及悬挂的研究[J]. 铁道学报, 2006, 28(6): 41-45. https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB200606007.htmLUO Y, SUN Y P, ZHANG H J, et al. Research on the motor arrangement and suspension of the six-axles locomotive with driving equipment mounted in the frame[J]. Journal of the China Railway Society, 2006, 28(6): 41-45. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB200606007.htm [8] 罗赟, 金鼎昌. 架悬机车驱动装置悬挂参数规律的研究[J]. 中国铁道科学, 2007, 28(4): 78-82. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTK200704019.htmLUO Y, JIN D C. Research on the rules of suspension parameters to driving equipments suspended in bogie frames[J]. China Railway Science, 2007, 28(4): 78-82. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTK200704019.htm [9] YAO Y, ZHANG H J, LUO S H. The mechanism of drive system flexible suspension and its application in locomotives[J]. Transport, 2015, 30(1): 69-79. [10] YAO Y, ZHAO S Y, XIAO F X, et al. The effects of wheelset driving system suspension parameters on the re-adhesion performance of locomotives[J]. Vehicle System Dynamics, 2015, 53(12): 1935-1951. doi: 10.1080/00423114.2015.1108446 [11] 缪炳荣, 张卫华, 池茂儒, 等. 下一代高速列车关键技术特征分析及展望[J]. 铁道学报, 2019, 41(3): 58-70. https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB201903009.htmMIAO B R, ZHANG W H, CHI M R, et al. Analysis and prospects of key technical features of next generation high speed trains[J]. Journal of the China Railway Society, 2019, 41(3): 58-70. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDXB201903009.htm [12] 贾洪龙, 尹振坤, 梁云, 等. 轨道车辆轴箱内置式转向架技术发展研究[J]. 城市轨道交通研究, 2021, 24(9): 59-63. https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT202109015.htmJIA H L, YIN Z K, LIANG Y, et al. Research on development of railway vehicle axle box in-board bogie technology[J]. Urban Mass Transit, 2021, 24(9): 59-63. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GDJT202109015.htm [13] 张隶新. 轴箱内置和外置高速转向架的动力学性能对比[J]. 铁道科学与工程学报, 2021, 18(3): 581-587. https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD202103004.htmZHANG L X. Dynamics analysis of high-speed railway bogies with inner bearing and outer bearing suspensions[J]. Journal of Railway Science and Engineering, 2021, 18(3): 581-587. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-CSTD202103004.htm [14] WU B W, CHEN G X, LYU J Z, et al. Effect of the axlebox arrangement of the bogie and the primary suspension parameters on the rail corrugation at the sharp curve metro track[J]. Wear, 2019, 426: 1828-1836. http://www.nstl.gov.cn/paper_detail.html?id=32b5781220d206bd0d1db81c0bf6f0d9 [15] 方凌昊, 关庆华, 温泽峰. 轴箱内、外置车辆轮轴弯曲对轮轨接触的影响[J]. 中南大学学报(自然科学版), 2022, 53 (8): 3259-3269. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202208040.htmFANG L H, GUAN Q H, WEN Z F. Influence of wheelset bending on wheel-rail contact of vehicles with inside and outside axle boxes[J]. Journal of Central South University(Science and Technology), 2022, 53(8): 3259-3269. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD202208040.htm [16] 郭峰, 刘建新, 吴圣川, 等. 轴箱布置方式对高速列车车轴承载性能的影响[J]. 机车电传动, 2022(1): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-JCDC202201001.htmGUO F, LIU J X, WU S C, et al. Effect of journal arrangement on load-bearing capacity of high-speed train axles[J]. Electric Drive for Locomotives, 2022(1): 1-7. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JCDC202201001.htm [17] 姜立标, 侯文超, 谷方德. 基于正交试验的汽车稳态回转性能仿真[J]. 北京航空航天大学学报, 2011, 37(8): 968-972. https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201108012.htmJIANG L B, HOU W C, GU F D. Steady state circular performance simulation of automobile based on orthogonal test[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(8): 968-972. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-BJHK201108012.htm [18] 曾元辰, 张卫华, 宋冬利. 基于车辆动力学和改进AGREE算法的高速列车稳定性综合可靠性分析[J]. 铁道机车车辆, 2018, 38(3): 10-16, 115. https://www.cnki.com.cn/Article/CJFDTOTAL-TDJC201803005.htmZEHG Y C, ZHANG W H, SONG D L. Comprehensive reliability analysis of high-speed trains stability based on vehi-cle dynamic and improved AGREE algorithm[J]. Railway Locomotive and Car, 2018, 38(3): 10-16, 115. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TDJC201803005.htm [19] 姜久林, 徐宏海, 蒋兴佳, 等. 高速列车轴箱轴承稳态温度场影响因素分析[J]. 机械传动, 2019, 43(11): 121-126. https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201911022.htmJIANG J L, XU H H, JIANG X J, et al. Analysis of the influencing factor on steady-state temperature filed of axlebox bearing for high speed train[J]. Journal of Mechanical Transmission, 2019, 43(11): 121-126. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JXCD201911022.htm -

下载:

下载: